Finished Bronze Pieta

The Marinelli Foundry was officially established in 1919 in Florence Italy. In 1932, the foundry entered into an important and enduring relationship with the Vatican for the commission of the bronze reliefs on the grand elliptical staircase for the new entrance of the Vatican museum. This established the relationship with the Vatican that lead to the foundry making molds of some of the most treasured art pieces in the Vatican collection. In 1932, a cast was made of Michelangelo’s original marble Pieta. A plaster positive was created from that original cast and exists today as the master mold of the original marble. A Limited Edition of 12 Original Bronze Sculptures by Michelangelo, the Pieta, were created, consisting of 3 foundry proof casts and 9 edition casts. The limited edition is sold out.

This is the only sculpture that bears the signature of Michelangelo. The original marble was sculpted when he was 24 years of age. It was rumored that such a young man could not have possibly sculpted such a masterpiece. Upon hearing this, he immediately carved his name into the sash that crosses Mary’s chest. Michelangelo later regretted his outburst of pride and swore never to sign another work of his hands.

In 2009, the original bronze Pieta # 2/3 FP (foundry proof) was placed at The Sanctuary of Our Sorrowful Mother (The Grotto) in Portland Oregon. It is currently on display in the Meditation Chapel on the upper level of the sanctuary gardens.

This is a look into an extraordinary project I have had the opportunity and privilege to be involved with. The Pieta # 2 of 3 FP is currently for sale, any inquiries are welcome.

60’H x 14’6”W x 14’6”D

Steel structure

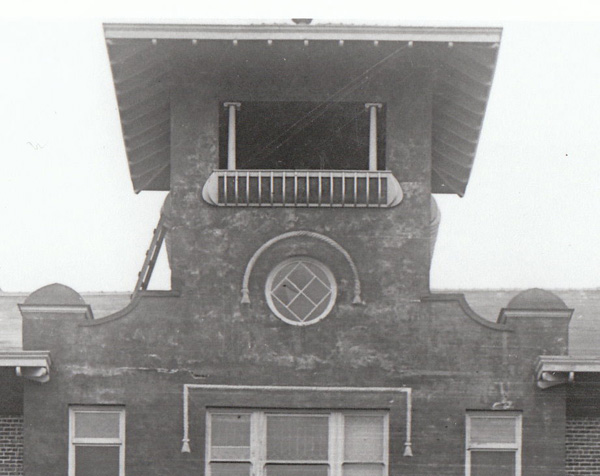

The recreation of the Bigham Knoll bell tower took place in 2008 and was a unique project, given the history of the building and the lack of information on the size of the tower. We took this old photo of the tower and scaled the size of the structure based on the existing windows that were original to the building, including the shape and design of the tower rail.

The recreation of the Bigham Knoll bell tower took place in 2008 and was a unique project, given the history of the building and the lack of information on the size of the tower. We took this old photo of the tower and scaled the size of the structure based on the existing windows that were original to the building, including the shape and design of the tower rail.

The steel structure for the tower was 60′ tall. The nature of the build was such that the main section of the tower itself had to be built outside of the building and set through the roof. The primary reason was to minimize the fire danger during the fabrication process.

The reality of lifting the 60′ steel structure over the roof and into place required the 120 ton Demag crane owned and operated by my brother-in-law Rick Cook. The job required all 165’ of boom extended into the air to reach over the building and set the tower.

The school had seen a lot of history along the way, including several fires. My father attended high school in this building and I went to 4th and 5th grade there.

The reconstruction is now complete. More information about Bigham Knoll is available at bighamknoll.com.

Recent Comments